FLOW3D WELD

Precise Simulation of Welding Processes

Virtual Welding Process Assurance for High-Precision Tasks

FLOW-3D WELD enables precise simulation of industrial welding processes, capturing material behavior during melting and solidification. Gain deep insight into melt pool behavior, heat-affected zones, porosity, and distortion, before mistakes turn into costly scrap, rework, or claims.

Skill Enhancement

Identify the optimal welding parameters to address your manufacturing challenges.

Process Stability

Increase your production output by ensuring quality in your welding process.

User-Friendlyness

Enable your users to access powerful simulation tools without requiring modeling experience or code modifications..

Solving Productions Problems

Design, stabilize, and assure welding process quality

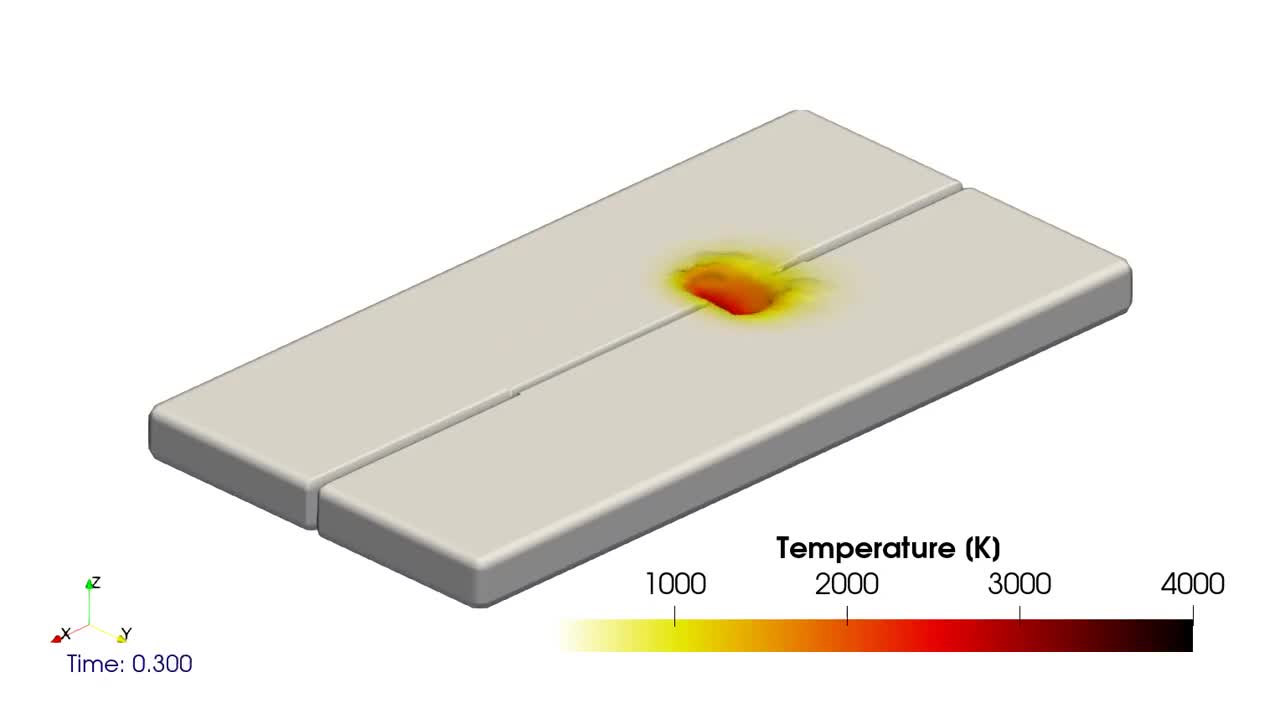

- Improve weld quality: Melt pool, keyhole, solidification and heat input are realistically simulated, allowing the appropriate process parameters to be identified early to avoid defects.

- Stabilize welding processes: Define robust parameters and avoid trial-and-errror testing.

- Shorten ramp-up: Test new materials, geometrics, and strategies with different parameters before being implemented in production.

- Cut costs: Accurate process parameters reduce the need for prototypes while improving first-part success.

Simulating Industrial Welding Processes

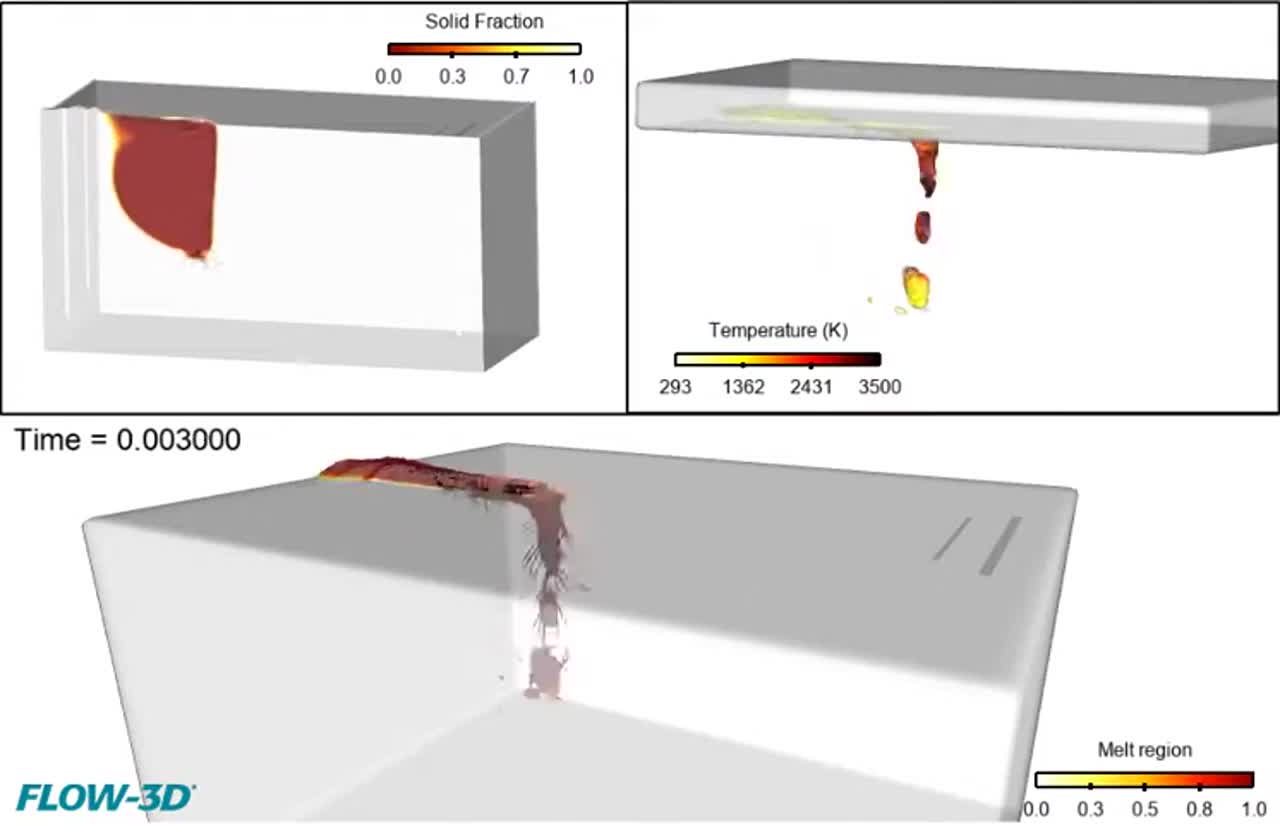

Laser Welding

Capture complex fluid flow and solidification during keyhole and conduction mode welding. Optimize weld schedules to improve joint quality, join dissimilar materials, increase production, and prevent critical defects such as porosity and cracking due to high thermal gradients and heat affected zones.

This ensures that welding processes are designed in a targeted manner, operated stably and quality-assured, before costs arise due to scrap, rework or complaints.

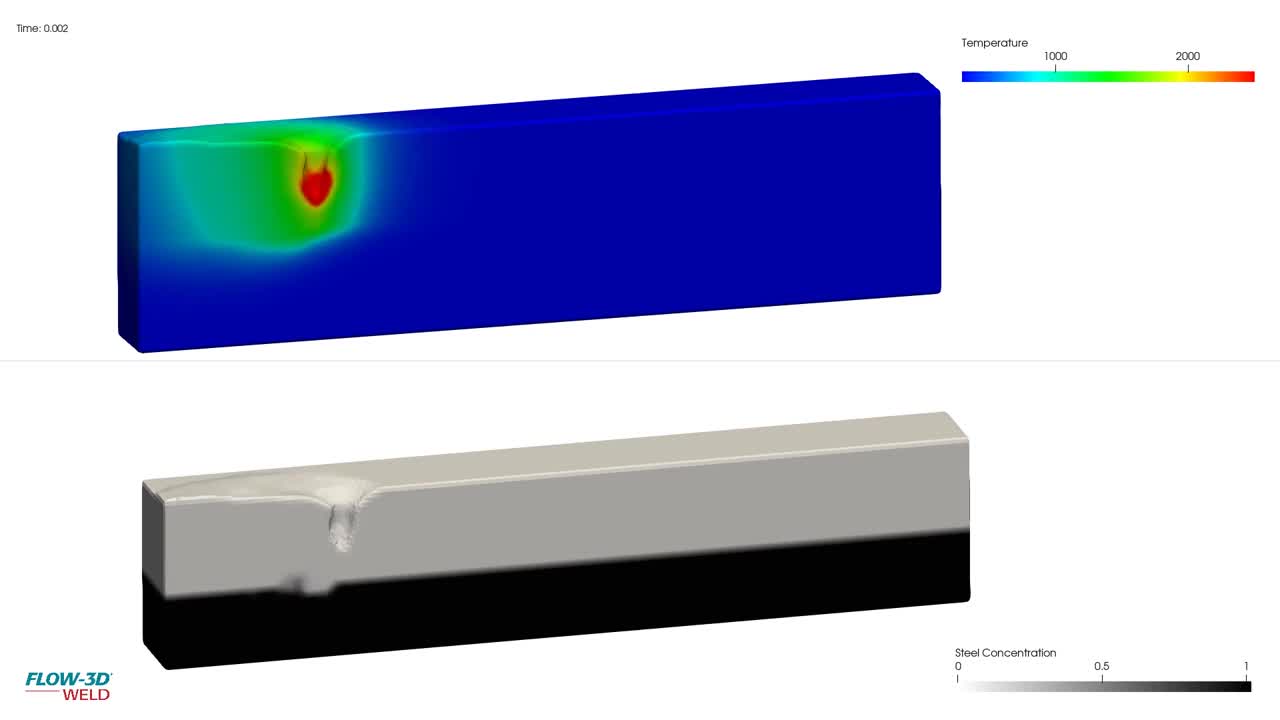

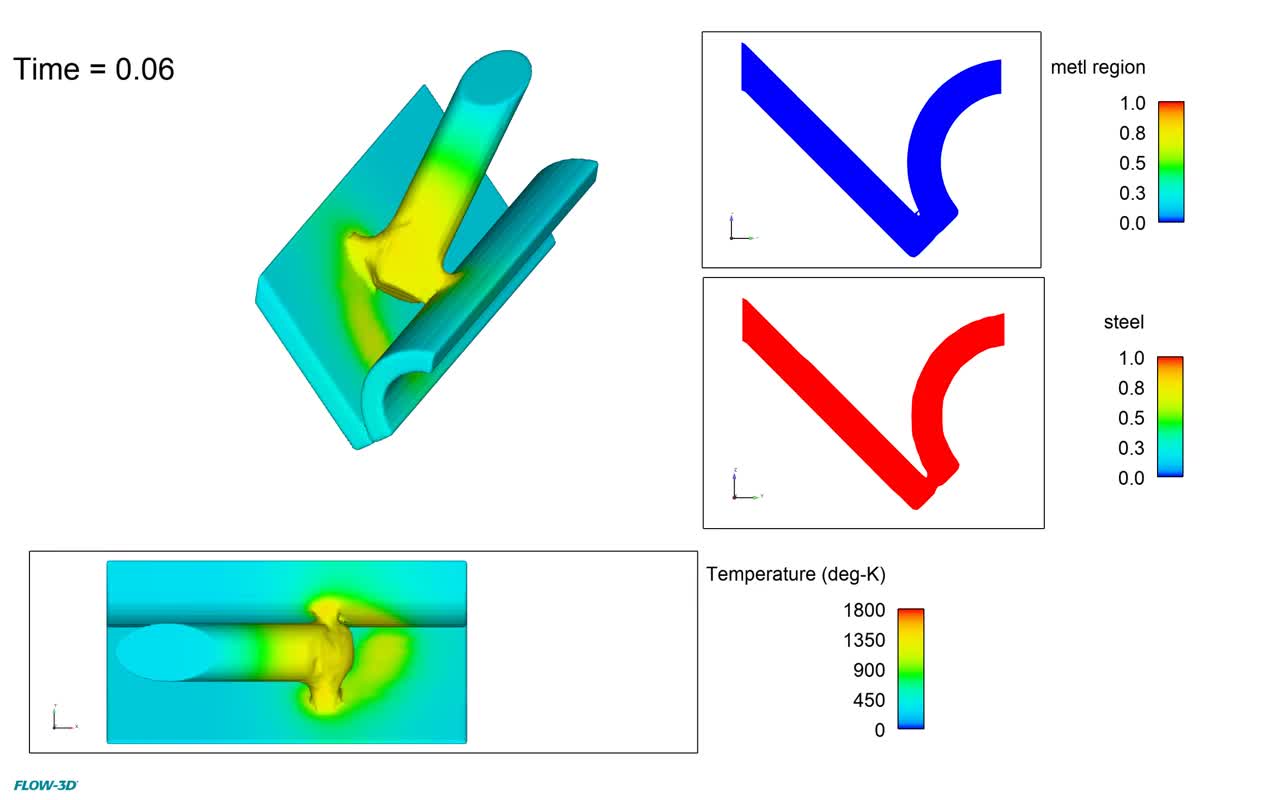

Welding of Dissimilar Metals

Simulate joining of dissimilar materials with accurate models accounting for the temperature dependent properties of each material. FLOW-3D WELD provides valuable insights into how variations in process parameters influence the inter-metallic layer and can lead to a reduction in porosity and crack propagation.

Pulse Welding

Utilize FLOW-3D WELD’s dynamic heat source options to model pulsed lasers and analyze their effect on your application. Identify optimal laser parameters and pulse durations to deliver precise heating in component sensitive areas or when joining dissimilar metals to avoid over mixing.

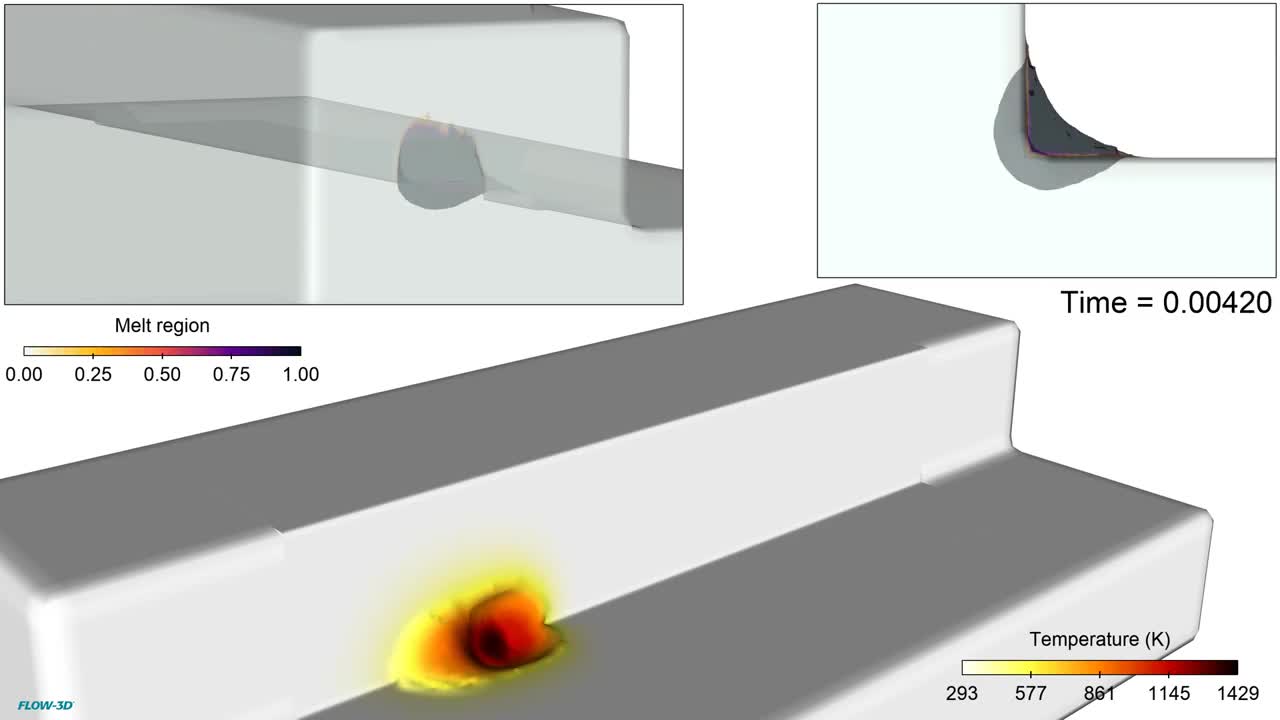

Oscillation Welding

Analyze the effects of different scan strategies, laser powers, and heat flux distributions while accounting for additional forces and heat transfer from recoil pressure, shield gasses, and laser reflections. Improve melt pool stability and joint quality through wobbling strategies that deliver precision heating with smaller heat affected zones.

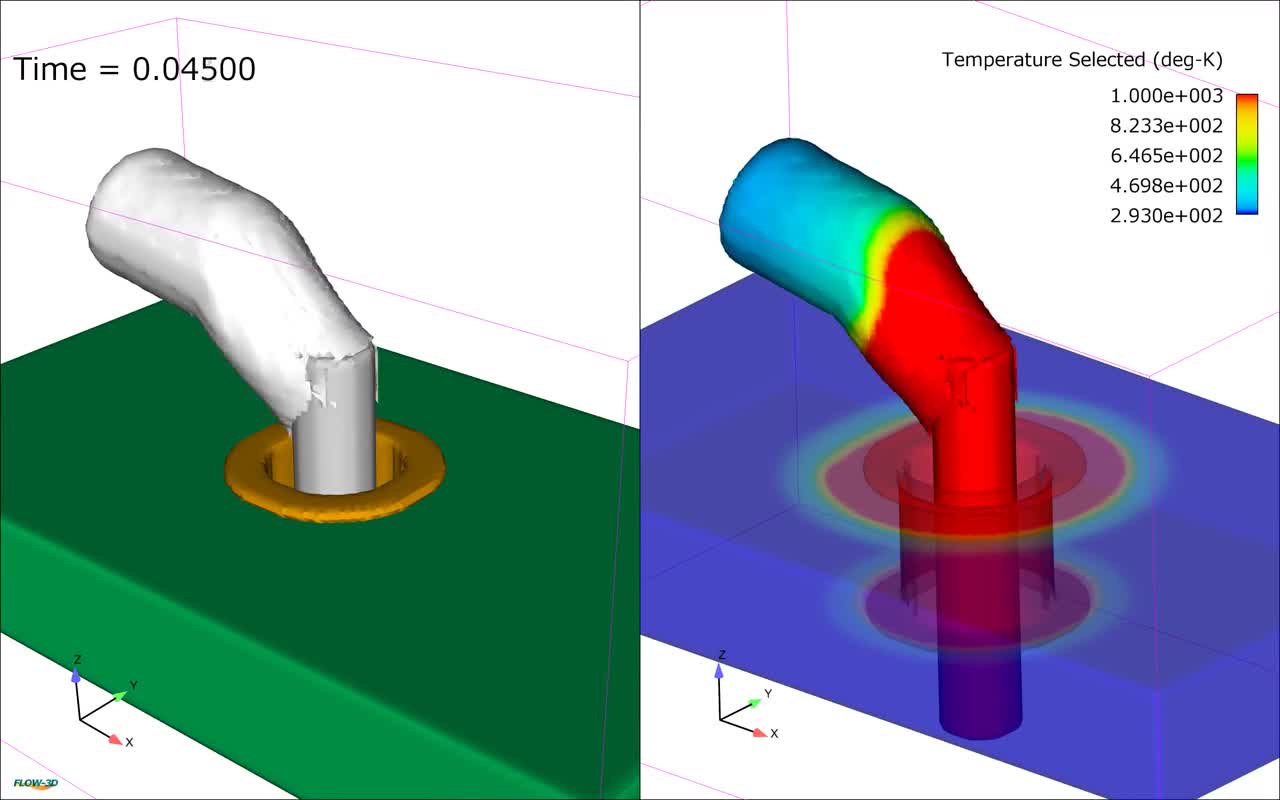

Laser Cladding

Simulate powder deposition with custom alloy definitions to understand effects of process parameters on coating quality. Optimize for desired surface finish and low heat affected zones when cladding onto sensitive components and maintaining tolerance stack requirements.

Laser Soldering

Simulate your soldering process to analyze the heat transfer around temperature sensitive components at the micro scale. Use FLOW-3D WELD to identify process parameters that result in high quality soldered joints while ensuring heat effected zones are not exceeding the maximum allowable temperatures.

Research Papers and Technical Presentations

Lern more about the application of FLOW-3D WELD or FLOW-3D AM in additive manufacturing, laser welding and other welding technologies in our bibliography.

See bibliographyReady for your next simulation?

Optimize your welding processes with FLOW-3D WELD before the first workpiece is manufactured: Develop more efficient processes, avoid defects, and increase the quality of your welds! We’ll show you how to quickly set up and optimize workflows and integrate them into your daily engineering routine.

Request a demo now