FLOW3D CAST

For Precise Casting Simulation and Rapid Process Optimization

Simulation Software for Modern Foundry Technology

Perfect Casting Begins in Simulation

With FLOW-3D CAST, you are using the most advanced simulation software for foundry technology. Our tool sets new standards in the virtual modeling of complex casting processes and significantly optimizes your product development.

Using FLOW-3D CAST helps our customers significantly improve casting quality, production efficiency, and development times – while reducing costs and strengthening competitiveness.

Understand, optimize, and master casting processes

FLOW-3D CAST is a state-of-the-art metal casting simulation modeling platform that combines extraordinarily accurate modeling with versatility, ease of use, and high performance cloud computing capabilities.

No prior experience is required; you’re ready to go immediately. Our FLOW-3D CAST software is clearly structured and intuitively designed, eliminating lengthy training periods. This allows you to focus on tackling your foundry challenges, supported by a truly game-changer tool.

Request a demo nowOne Powerful Software – All Casting Processes

Accelerate the Way You Achieve Superior Cast Parts

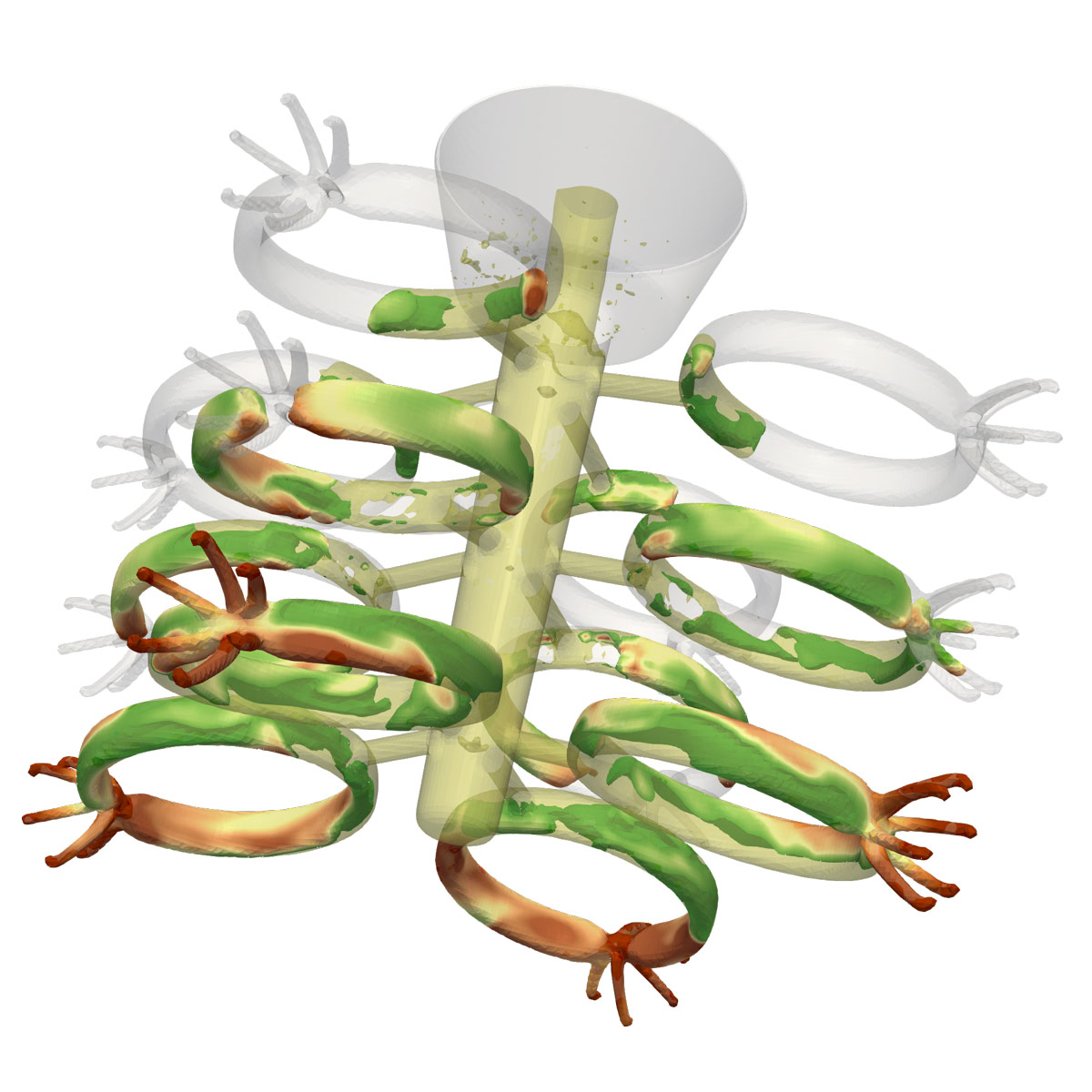

FLOW-3D CAST covers all relevant casting processes. Thanks to dedicated workspaces for each application, you start with optimal presets and customized functions. The application is intuitive and easy to use from the outset. Based on years of development by our foundry engineers, you work immediately with validated settings. This allows you to simulate quickly, reliably, and without complicated detours.

Your Key Benefits at a Glance

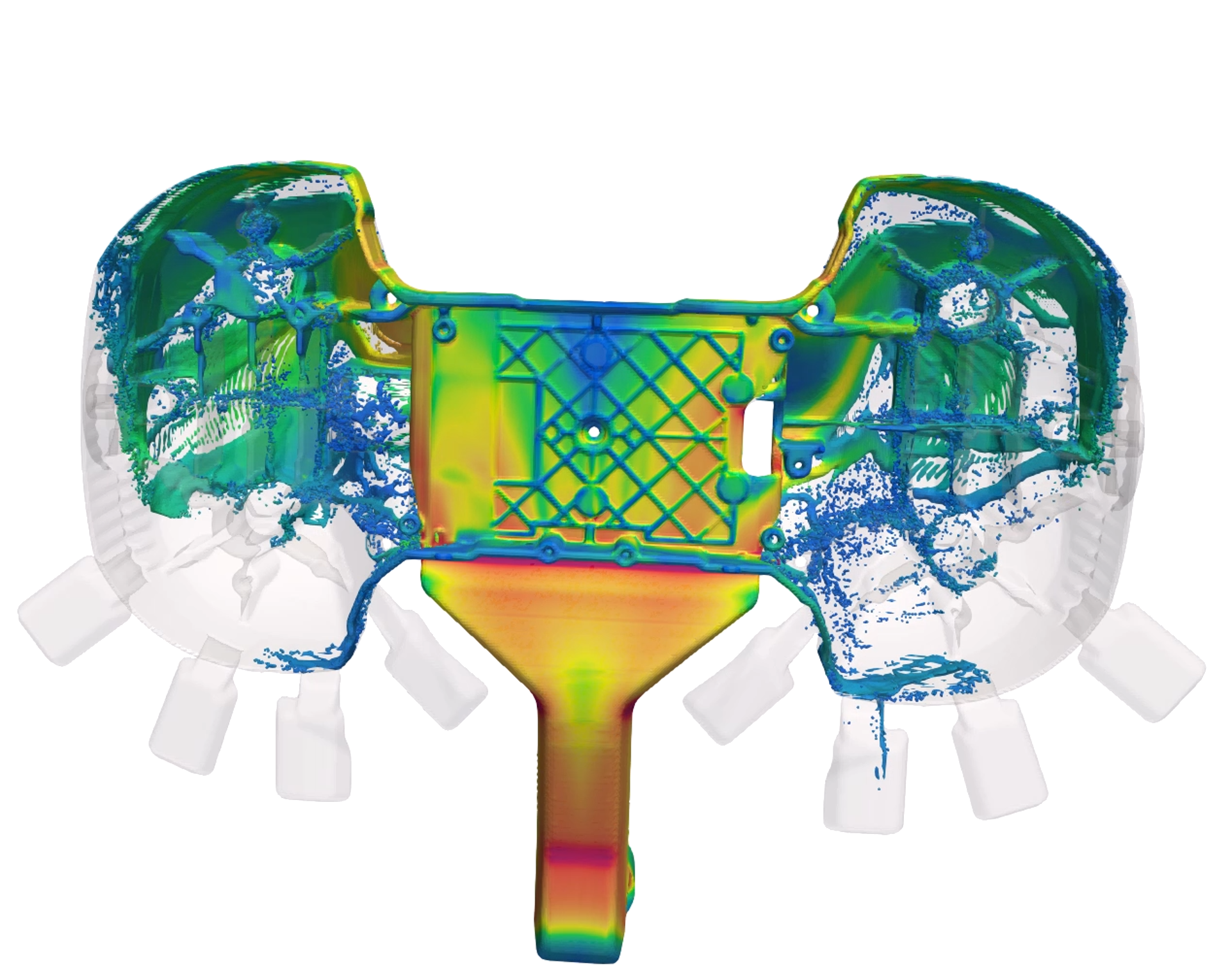

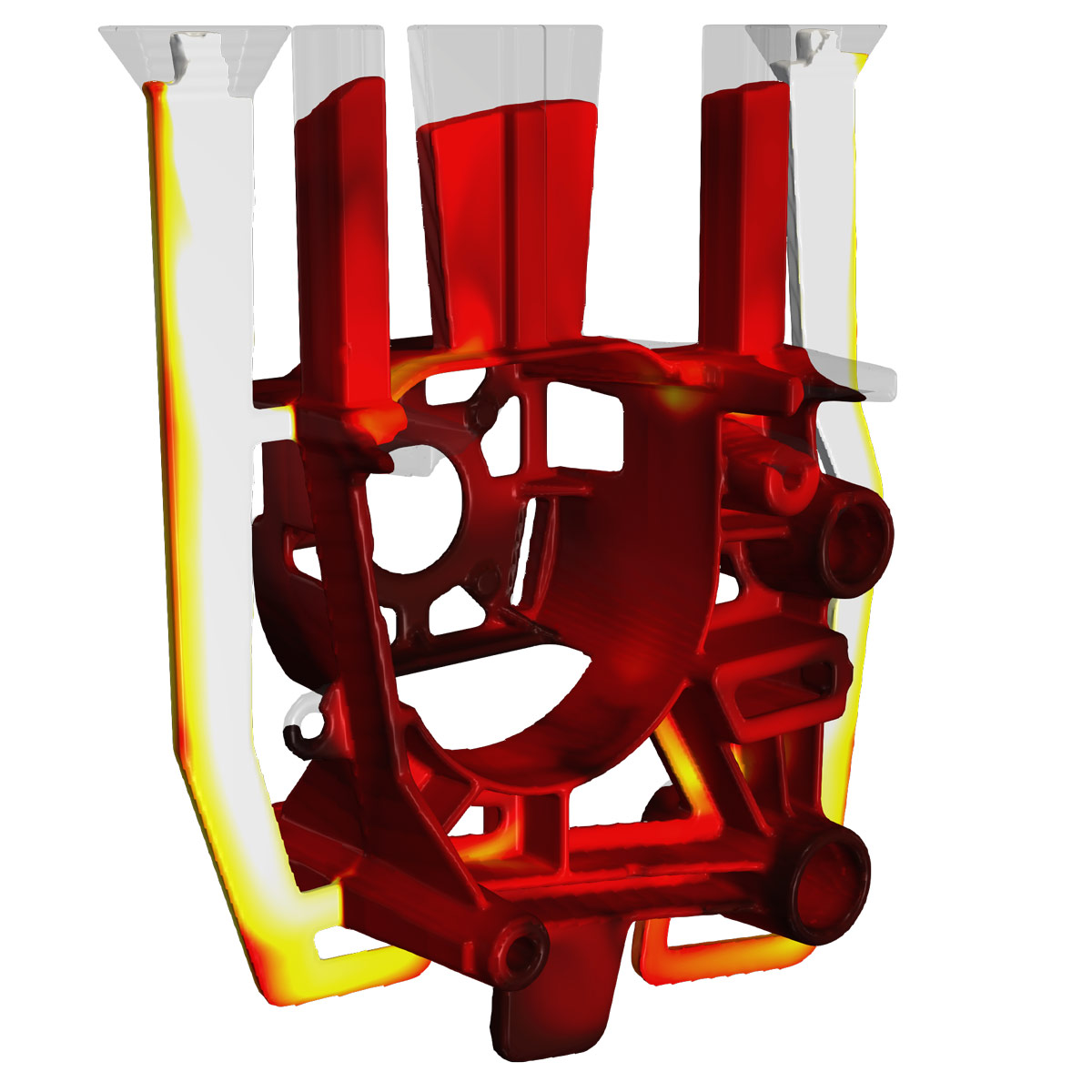

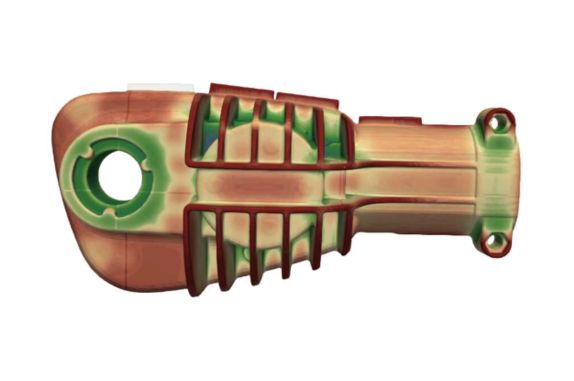

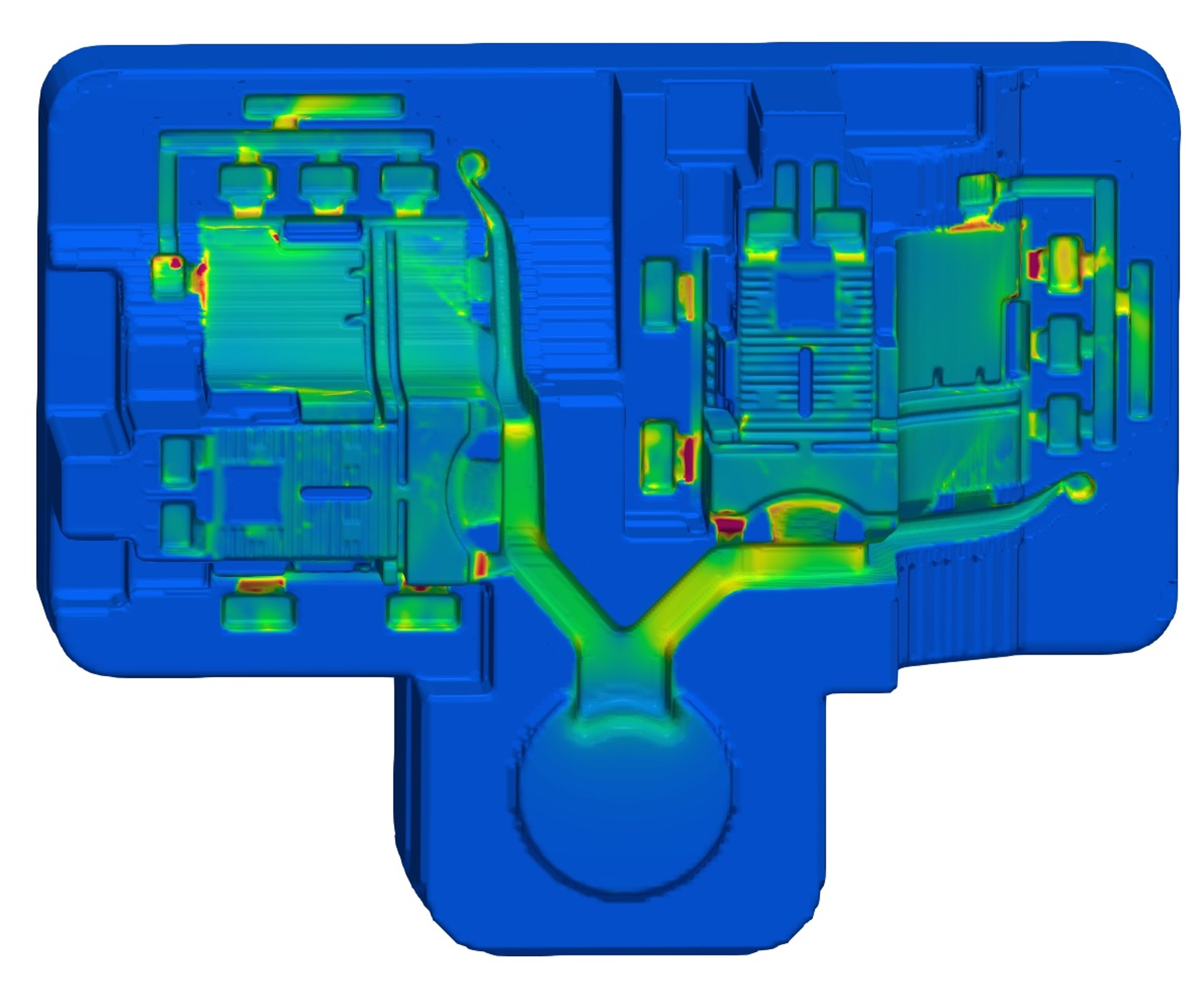

FLOW-3D CAST delivers detailed predictions of solidification, microstructure, distortion, and residual stresses, helping you reduce risk and maximize production efficiency.

Casting Quality

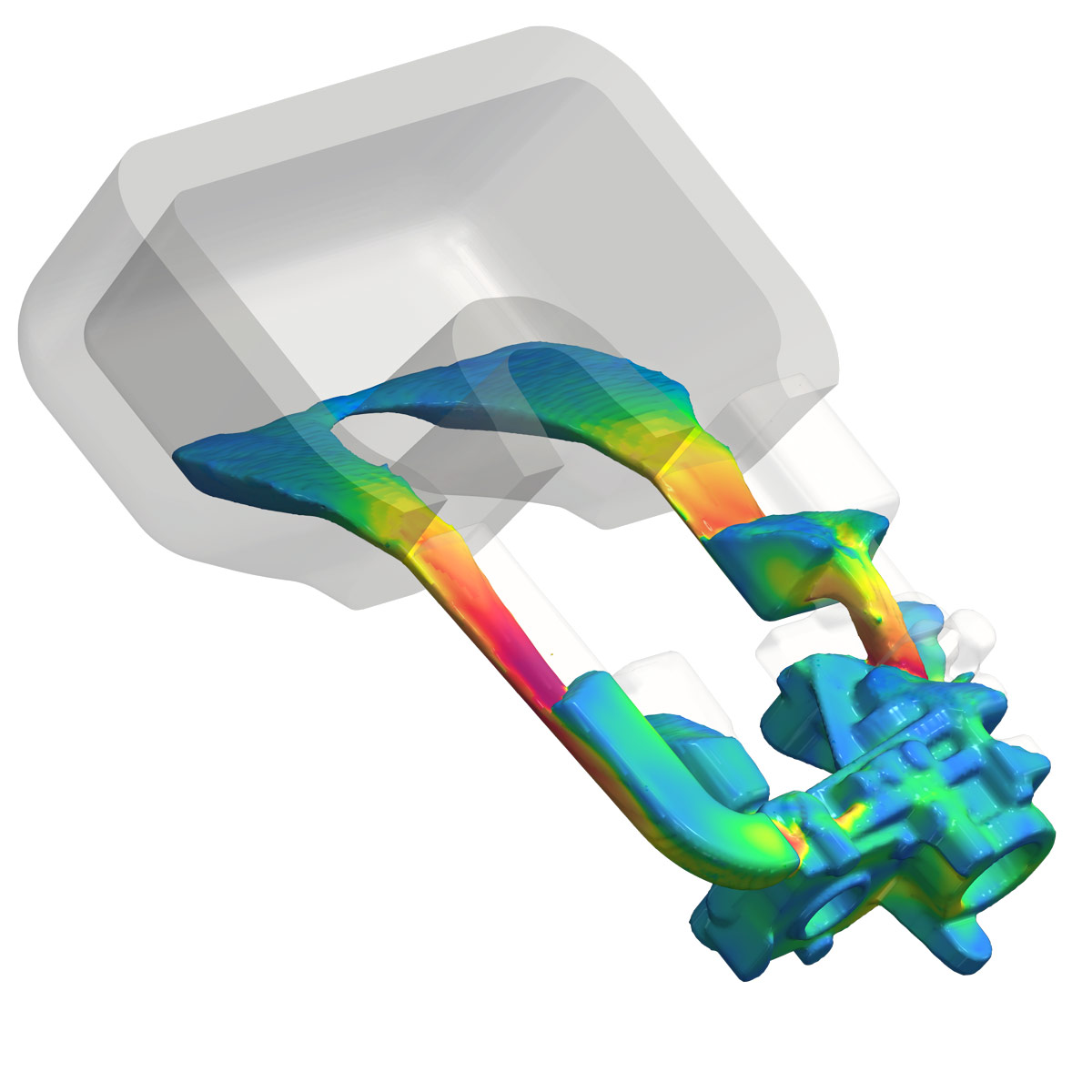

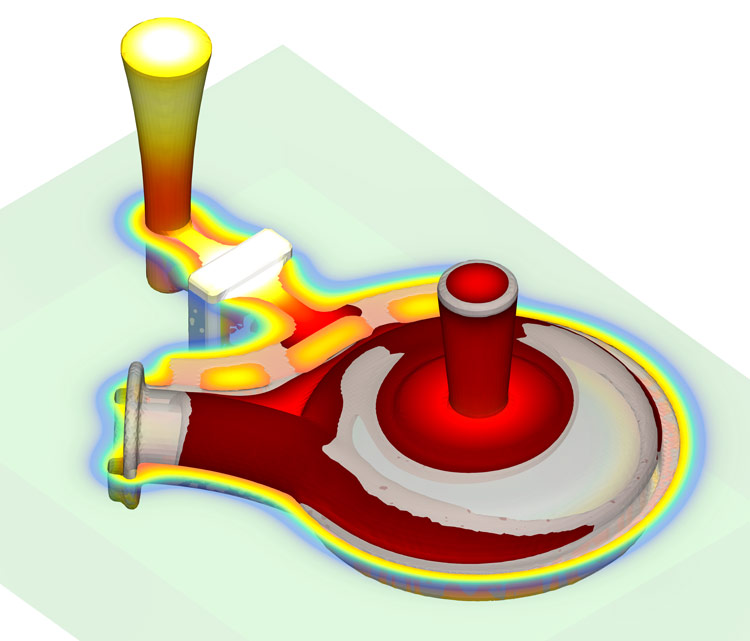

- Early identification of typical casting defects such as air inclusions, oxides, cold shuts, porosity, and hot cracking

- Prediction of microstructure, mechanical properties, residual stresses, and distortion

Casting Technology

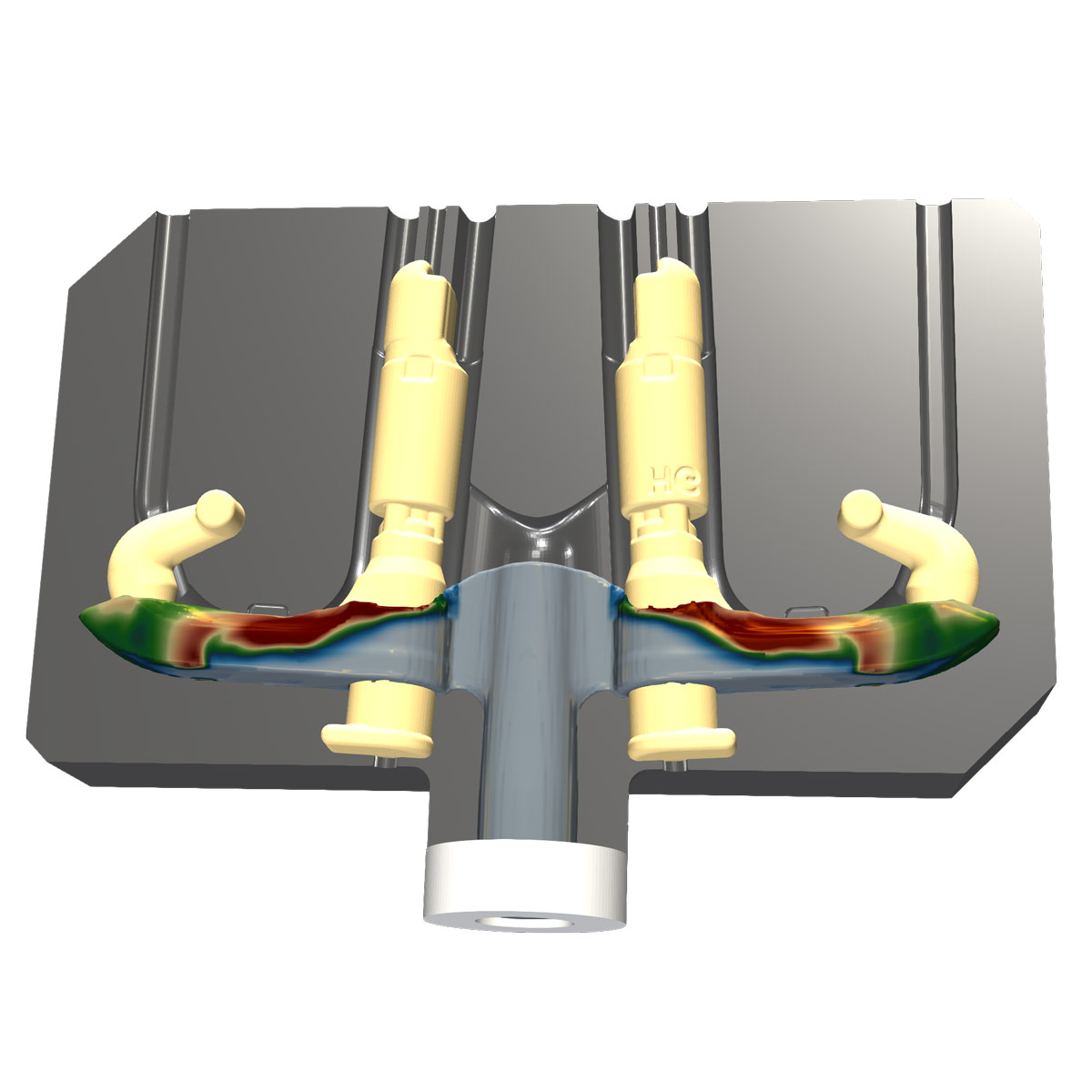

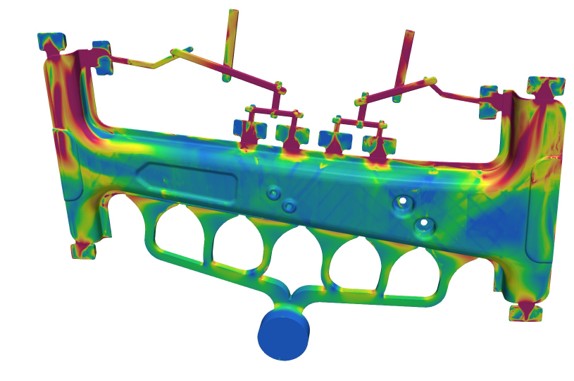

- Design and positioning of gates, runners, and venting systems based on flow, solidification, and cycle simulations

- Analysis of turbulence, air entrapment, flow interruptions, and critical filling regions

Tool and Mold

- Simulation of mold-related damage such as erosion, cavitation, adhesion, or cracking

- Visualization of thermal behavior and cooling conditions during temperature fluctuations over multiple cycles

Casting Process

- Identification of optimal process parameters, including shot profile, PQ² analysis, die temperature, and metal temperature, as well as cycle time optimization

- Reduction of scrap and rework material

Physical Accuracy Meets Ease of Use

FLOW-3D CAST provides deep insight into solidification, microstructure, distortion, and residual stresses, enabling safer, more efficient production planning

Technical Highlights

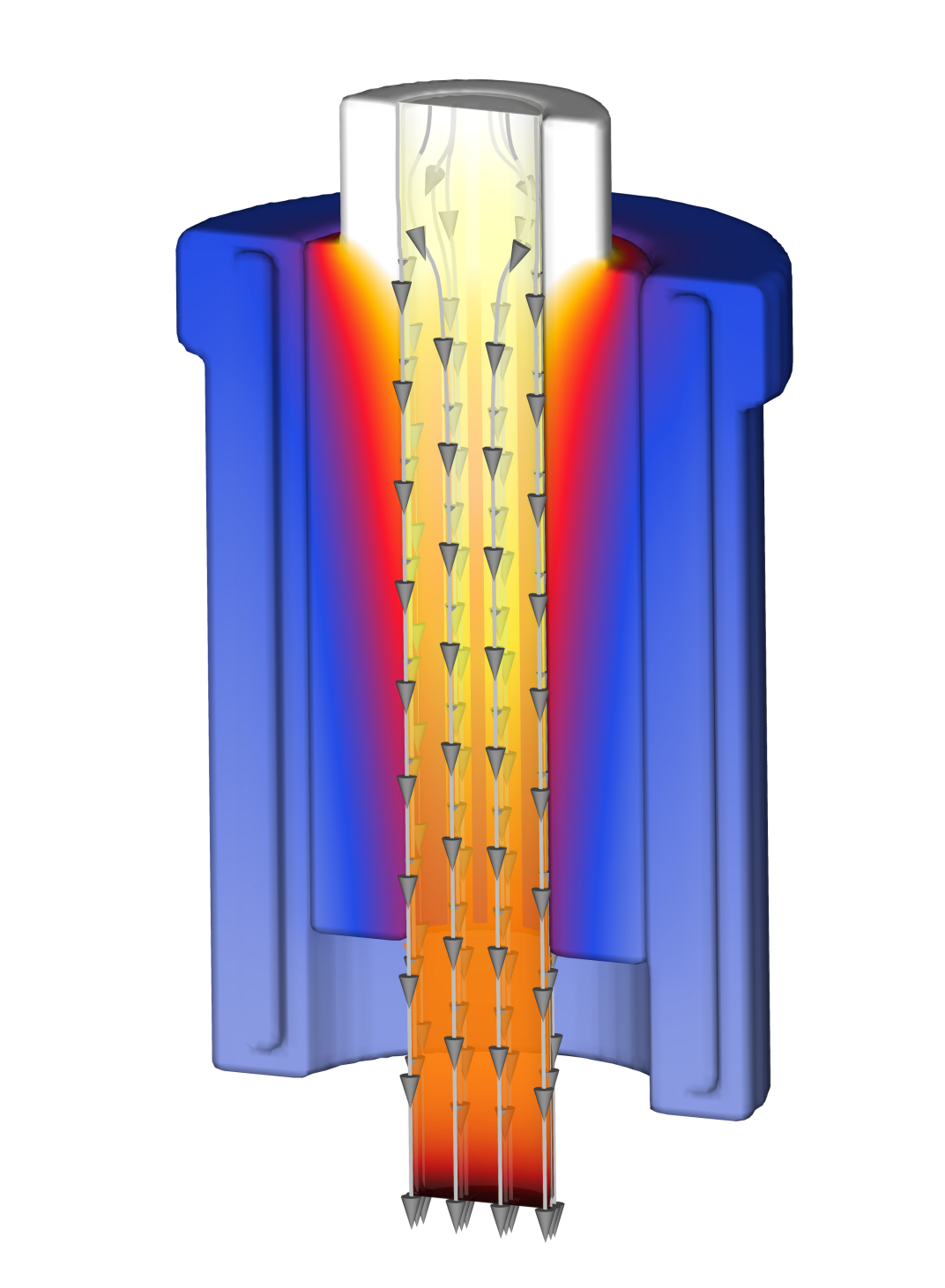

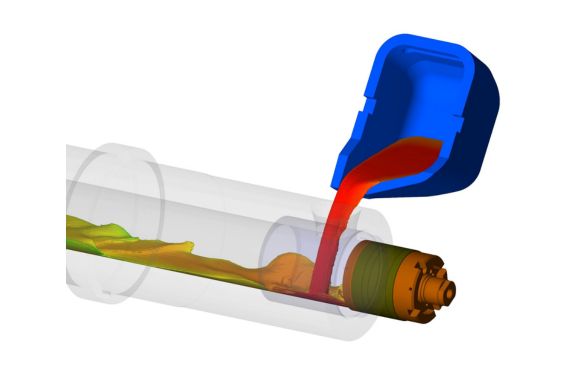

Highest Accuracy in Filling Simulations

TruVOF™ process in combination with FAVOR™ or the exact mapping of free surfaces and complex tool geometries.

Comprehensive Physical Models

Chemistry-based solidification model including segregation, latent heat, and alloy influence. Turbulence, surface tension, cavitation, and heat and mass transfer are fully considered.

Simulation of Moving Components

Accurate modeling of piston, ladle, slider as well as other dynamic components.

Mesh Generation

Simple and intuitive mesh generation, well suited for complex flow and solidification processes.

Experience Casting Simulation up close

FLOW-3D CAST is designed to make it easy for anyone to get started with simulating casting processes. helping you deliver measurable value to your business faster.

Upcoming Dates

Meet our casting simulation experts here soon:

Your next step towards precise casting simulation

Shorten development times and increase your process reliability with FLOW-3D CAST.

Request a demo now